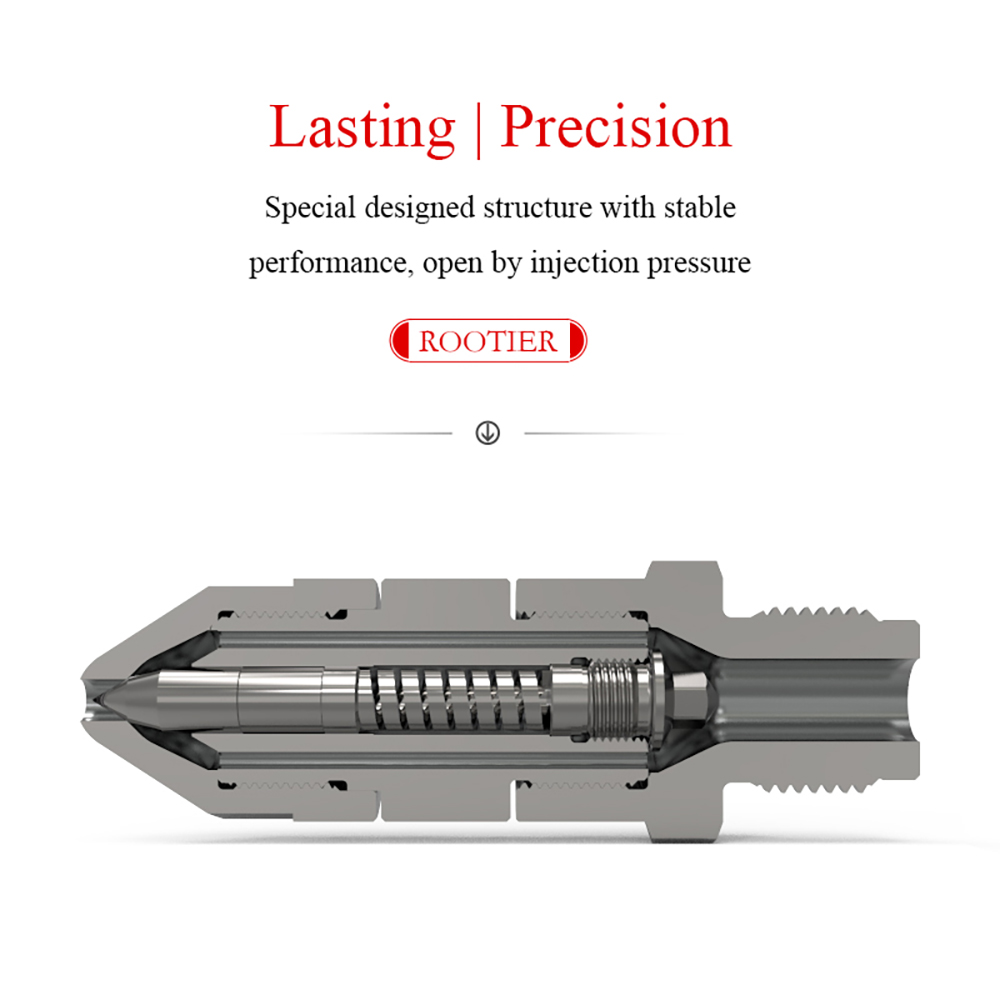

Plastic Injection Molding Machine Spring Shut-off Nozzle

Internal spring controlled shut-off nozzle mainly serves to solve the leakage of low density thermoplastic injection process, like PA, PP, PS, PE, which can improve production efficiency and save production cost, and it’s used lot in low-frequency injection process.

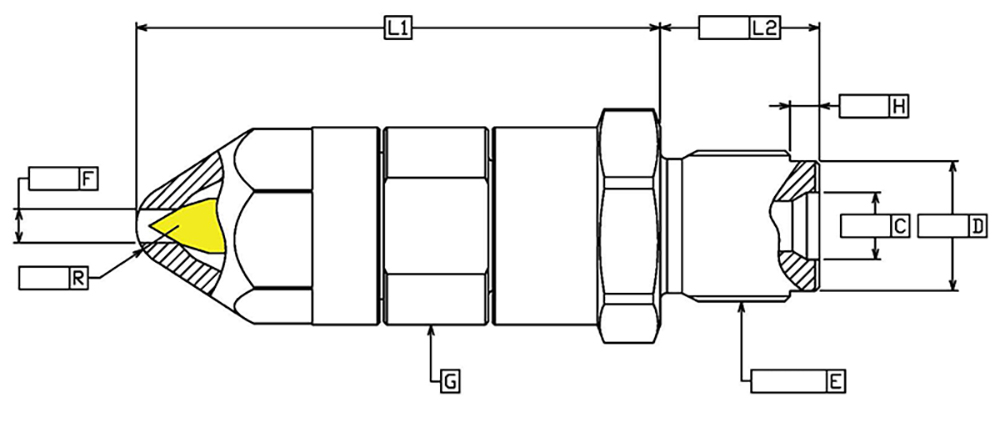

| PARAMETER | RS-I | RS-II | ||||

| Max. Shot Weight (Ref.) | gram | 1000 | 5000 | |||

| Max. Screw Size (Ref.) | mm | 70 | 120 | |||

| Body Length (L1) | mm | 123 | 135 | |||

| Hexagon (S/W) | mm | 50 | 60 | |||

| Heater Size (G) | mm | Φ47x60L | Φ60x80L | |||

| Open Pressure (Ref.) | Bar | 280 | ||||

| Close Pressure (Ref.) | Bar | 100 | ||||

| Max. Inj. Pressure (Ref.) | Bar | 2500 | ||||

| Max. Temperature | °C | 380 | ||||

| REQUIRED MEASUREMENT | ||||||

| C | D | E | H | L2 | F | R |

Internal spring controlled shut-off nozzle mainly serves to solve the leakage of low density thermoplastic injection process, like PA, PP, PS, PE, which can improve production efficiency and save production cost, and it’s used lot in low-frequency injection process.

The needle is drove by internal spring and keep shutting automatically, during injection process, the injection pressure force the needle back to open the channel and ensure proper injection, after injection ends, pressure drops and needle will again lockup by spring and prevent material from leaking out of nozzle.